Manufacturing Process

The manufacturing of this Basketball Court Wood Flooring follows a strict and sophisticated process to ensure the final product meets the highest quality standards.

Raw Material Selection: The first step is to carefully select high – quality wood. We mainly choose hard woods such as maple and oak, which have excellent hardness, wear resistance, and elasticity. These woods are sourced from legally certified forests to ensure environmental protection and sustainability. Each piece of wood is inspected for defects such as knots, cracks, and discoloration, and only the qualified ones are selected for further processing.

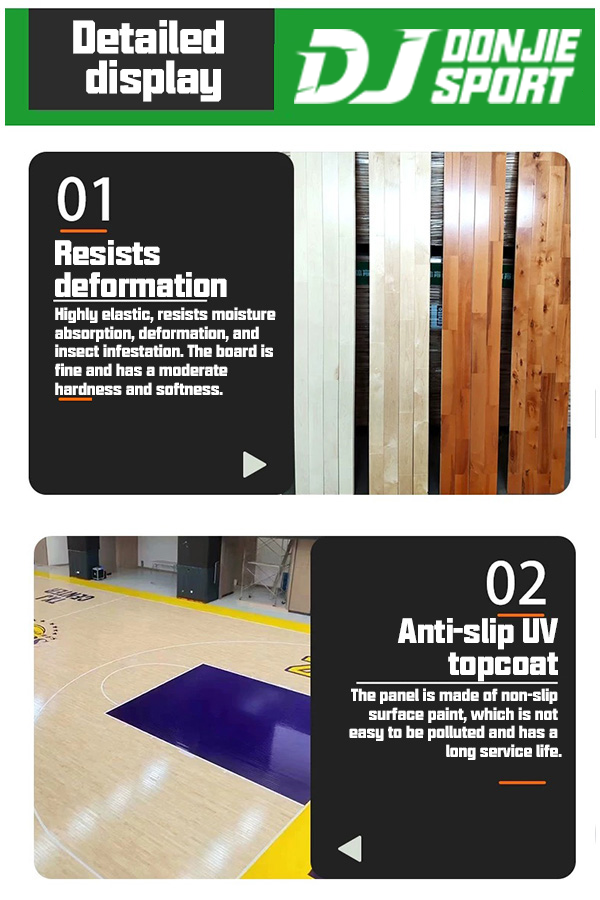

Drying Treatment: The selected wood is sent to a professional drying workshop for drying treatment. We use a combination of natural drying and artificial drying (such as kiln drying) to reduce the moisture content of the wood to an optimal range (usually 6% – 12%). This step is crucial to prevent the wood from warping, cracking, or deforming during use, ensuring the stability of the flooring.

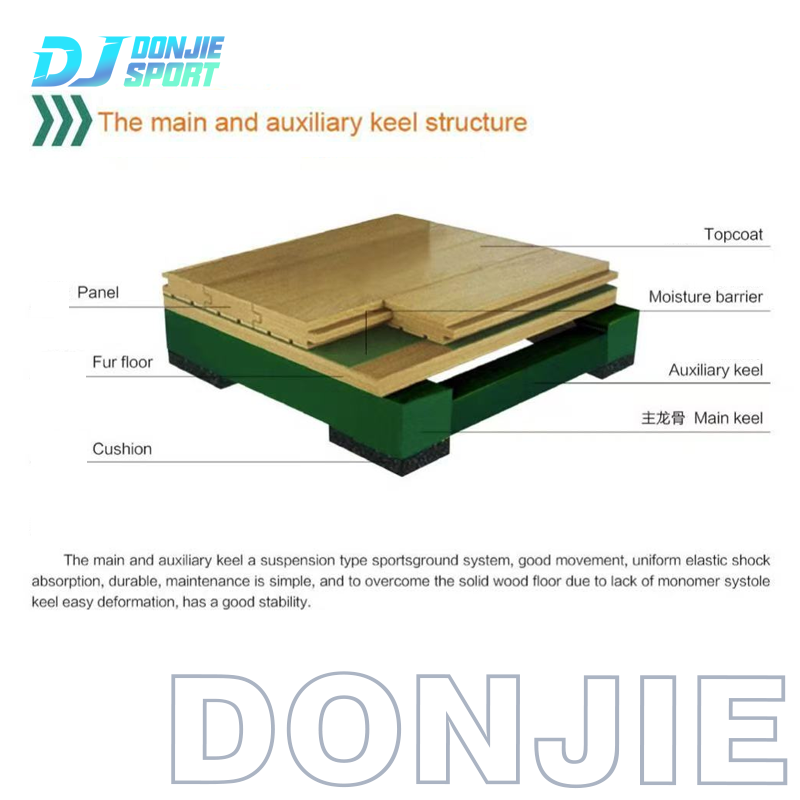

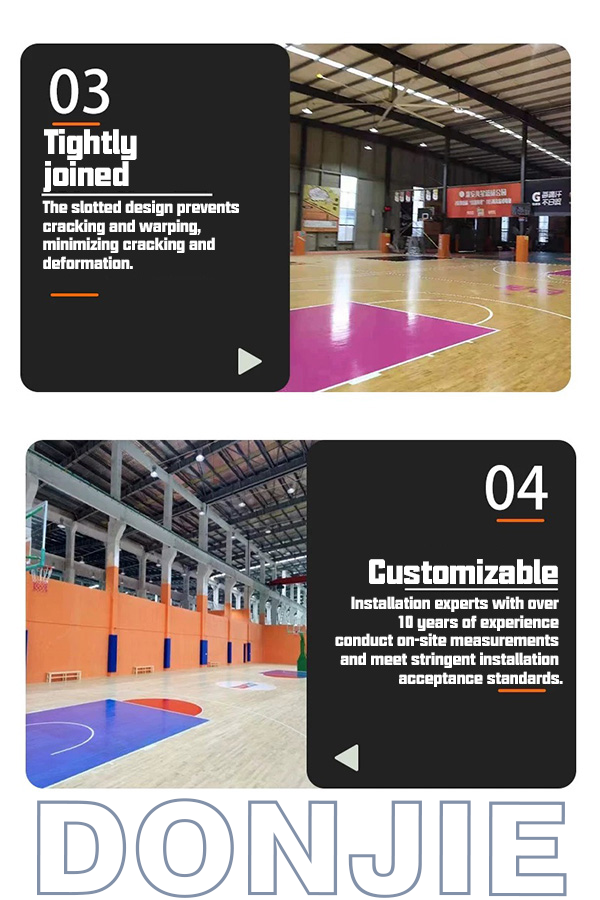

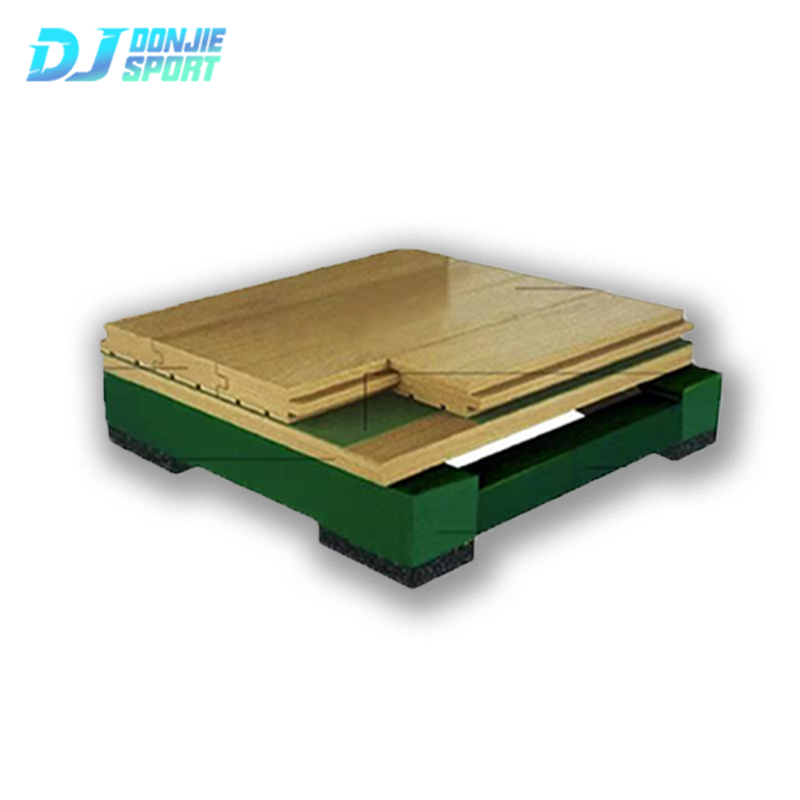

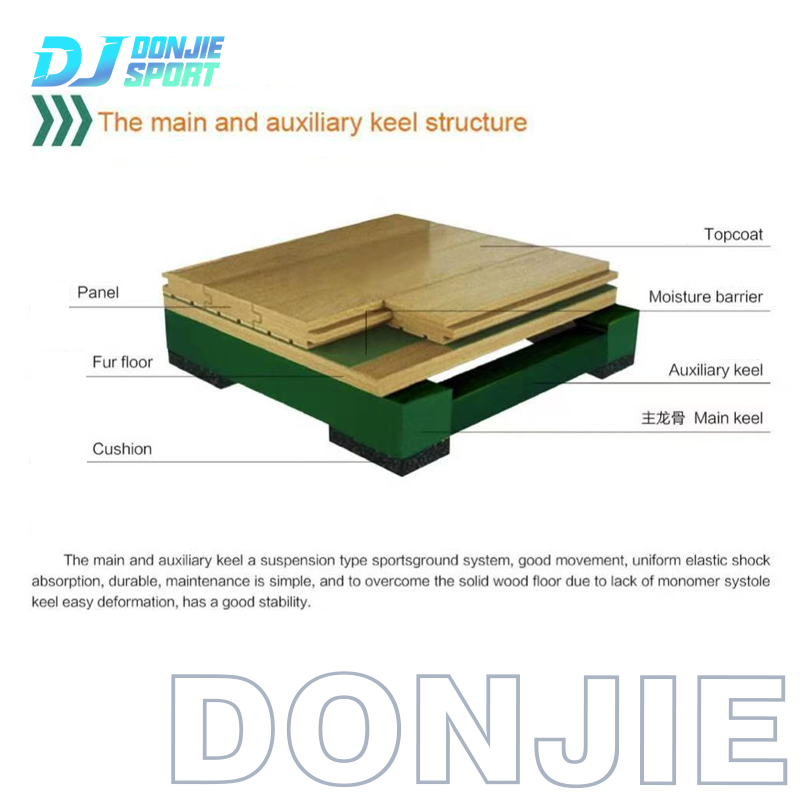

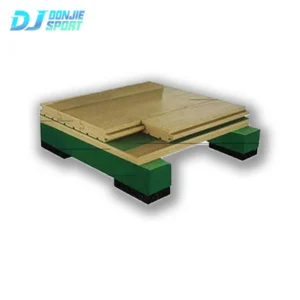

Processing and Milling: After drying, the wood is processed into planks of specific sizes and shapes. First, the wood is cut into rough planks, and then it undergoes processes such as planing, sanding, and milling. The surface of the planks is sanded to be smooth and flat, and the edges are milled to form a tongue – and – groove structure. This tongue – and – groove design allows the planks to be tightly connected during installation, enhancing the overall stability of the flooring.

Surface Treatment: The processed planks are then subjected to surface treatment. First, a primer coat is applied to seal the wood surface and enhance the adhesion of the subsequent coating. After the primer is dried, a sanding process is carried out to make the surface more smooth. Then, multiple coats of topcoat (usually polyurethane coating) are applied. The topcoat has excellent wear resistance, scratch resistance, and anti – slip properties, which can protect the wood surface and extend the service life of the flooring. In addition, the topcoat can also enhance the appearance of the flooring, making the wood grain more clear and beautiful.

Quality Inspection: After the surface treatment is completed, each plank of the Basketball Court Wood Flooring undergoes a strict quality inspection. Inspectors check the dimensions, flatness, surface finish, and physical properties (such as hardness, wear resistance, and shock absorption) of the planks. Only the planks that pass all the inspection items are allowed to enter the next step of packaging.

Assembly into Parquet: For parquet flooring, the qualified planks are assembled into parquet panels according to the designed patterns. The assembly process requires high precision to ensure that the patterns are neat and the connection between the planks is tight.

Material Introduction

The material of this Basketball Court Wood Flooring is the key factor determining its performance and quality.

Core Wood Material: As mentioned earlier, we mainly use high – quality hard woods such as maple and oak.

Maple Wood: Maple wood is one of the most popular materials for basketball court flooring. It has a fine and uniform texture, high hardness (with a Janka hardness rating of about 1450), and excellent elasticity. When athletes jump and land on the maple wood flooring, it can absorb part of the impact force, reducing the pressure on the joints and muscles, thus reducing the risk of sports injuries. In addition, maple wood has good wear resistance, which can withstand the frequent movement and friction of athletes’ shoes.

Oak Wood: Oak wood is also a good choice for basketball court flooring. It has a dense structure, high hardness (Janka hardness rating of about 1360), and strong durability. Oak wood has good dimensional stability, which is not easy to be affected by changes in temperature and humidity, ensuring the long – term stability of the flooring. The wood grain of oak wood is beautiful and unique, which can add a touch of elegance to the indoor basketball venue.

Coating Material: The coating used on the surface of the flooring is a high – quality polyurethane coating. This coating is non – toxic, environmentally friendly, and has excellent performance. It has strong adhesion to the wood surface, which is not easy to peel off. The polyurethane coating has good wear resistance, which can resist the scratch and wear caused by athletes’ shoes and basketball. It also has good anti – slip properties, even when the surface is slightly wet, it can provide sufficient friction to prevent athletes from slipping. In addition, the coating has good resistance to yellowing and aging, which can keep the flooring’s appearance bright and new for a long time.

Auxiliary Materials: In addition to the core wood material and coating material, some auxiliary materials are also used in the Basketball Court Wood Flooring to ensure its installation and performance. For example, the underlayment material, which is usually made of cork, rubber, or foam. The underlayment can play a role in shock absorption, sound insulation, and moisture prevention. It can reduce the impact of the flooring on the ground, reduce the noise generated during the use of the flooring, and prevent the moisture in the ground from penetrating into the flooring, thus protecting the flooring.

Packaging and Shipping

We pay great attention to the packaging and shipping of this Basketball Court Wood Flooring to ensure that the products can reach the customers safely and intactly.

Packaging:

Inner Packaging: Each plank or parquet panel is wrapped with a layer of plastic film to prevent moisture, dust, and scratches during transportation. For some high – end products, we may also use kraft paper or foam sheets to provide additional protection.

Outer Packaging: The wrapped planks or panels are then packed into strong cartons or wooden crates. The cartons are made of high – quality corrugated cardboard, which has good compression resistance and impact resistance. The wooden crates are made of solid wood, and the joints are reinforced with nails or screws to ensure the stability of the crates. In addition, we will add a layer of foam or bubble film between the products in the cartons or crates to prevent collision and friction between the products.

Labeling: Each package is labeled with clear and detailed information, including the product name (Indoor Basketball Court Parquet Sports Wood Flooring), product model, quantity, batch number, production date, weight, dimensions, and the customer’s name and address. This helps in the identification, storage, and transportation of the products.

Shipping:

Transportation Methods: We offer a variety of transportation methods to meet the different needs of customers, including sea freight, air freight, and land freight (truck transportation). Sea freight is suitable for large – quantity orders and long – distance transportation, which has the advantage of low cost. Air freight is suitable for urgent orders and small – quantity orders, which has the advantage of fast speed. Land freight is suitable for short – distance transportation within the same country or region, which is convenient and flexible.

Transportation Partners: We cooperate with well – known and reliable logistics companies with rich experience in transporting building materials. These logistics companies have a complete transportation network and professional transportation teams, which can ensure the safe and timely delivery of the products.

Tracking and After – sales Service: After the products are shipped, we will provide the customer with the tracking number of the shipment. The customer can track the transportation status of the products in real – time through the logistics company’s official website or customer service. During the transportation process, if there is any problem with the products (such as damage, loss, etc.), we will work closely with the logistics company to solve the problem for the customer in a timely manner, ensuring the customer’s interests are not affected.