Versatile Application Scenarios

Our basketball wooden sports flooring is tailored to diverse indoor athletic environments, ensuring consistent performance across usage intensities:

Professional Venues: Meets FIBA (Fédération Internationale de Basketball) requirements for national/international tournaments, with 90%+ ball rebound rate and calibrated shock absorption to protect pro athletes’ joints .

Educational Institutions: Ideal for university gymnasiums and high school training halls, balancing durability for daily practice with safety for teen athletes .

Commercial & Recreational Spaces: Enhances basketball courts in sports clubs, fitness centers, and private villas, merging premium wood aesthetics with functional performance .

Multipurpose Halls: Compatible with secondary uses like volleyball or badminton, thanks to its stable load-bearing capacity and uniform surface .

Precision Manufacturing Process

Every plank undergoes 32+ rigorous Process (45+ days total) to ensure structural integrity and athletic performance :

Raw Material Selection & Preparation

Sourcing 50–80-year-old hard maple, oak, or beech logs (core material only, no knots/cracks) for natural elasticity and density .

Automated moisture control: Kiln-drying for 10 days to adjust 含水率 to 8–12% (north regions) or 10–14% (south regions), eliminating internal stress and preventing warping .

Precision Processing

High-precision cutting: Sliced into 20–24mm thick blanks (common specs: 1860×140×20mm) with ±0.2mm width tolerance .

Tenon-mortise joining: Hydraulic-calibrated tongue-and-groove connections (seam error ≤0.3mm) for tight, gap-free assembly .

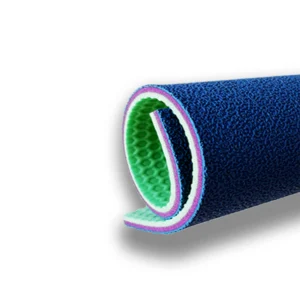

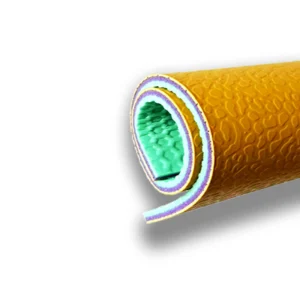

Multi-layer compounding (for composite models): 3mm high-density birch surface + 8mm cross-laminated core + 2mm moisture-proof silica gel base for balanced flexibility and load-bearing .

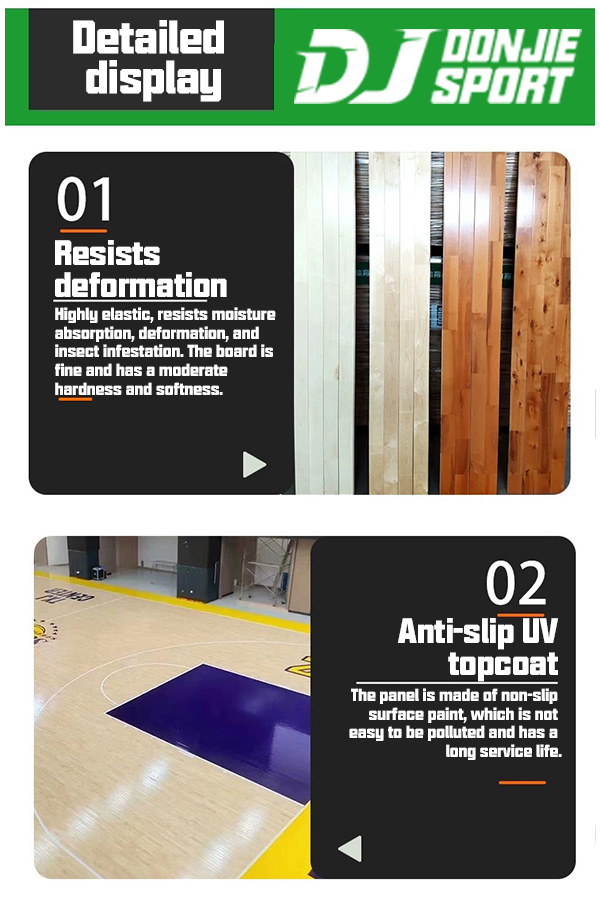

Surface Finishing & Quality Inspection

Triple sanding: 6-axis CNC sanding for ≤0.5mm/㎡ flatness .

Eco-friendly coating: 4 primer + 2 topcoat solvent-free UV paint system, forming a 0.5mm anti-slip layer (friction coefficient 0.4–0.6) .

Strict testing: Passes 150kg impact resistance (1.5m drop), wet-condition slip resistance (dynamic friction ≥0.3), and low formaldehyde emission (<0.02mg/m³, exceeding EU standards) .

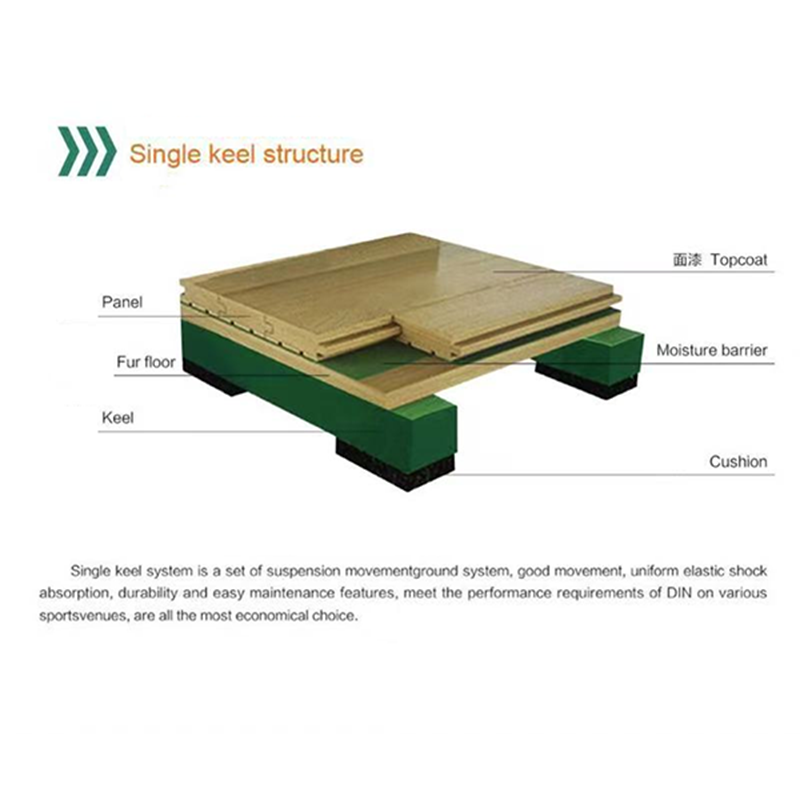

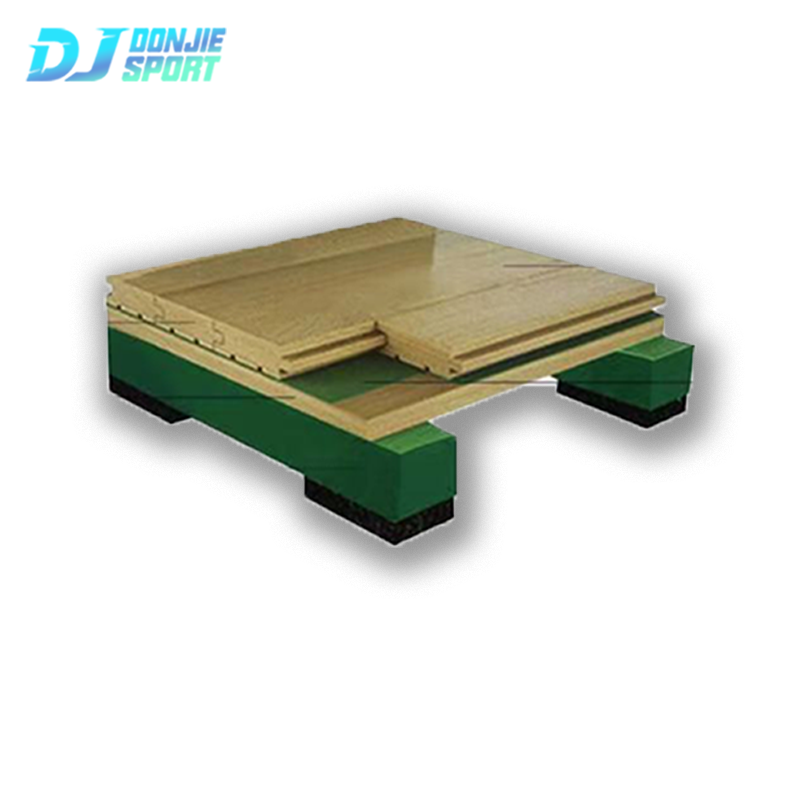

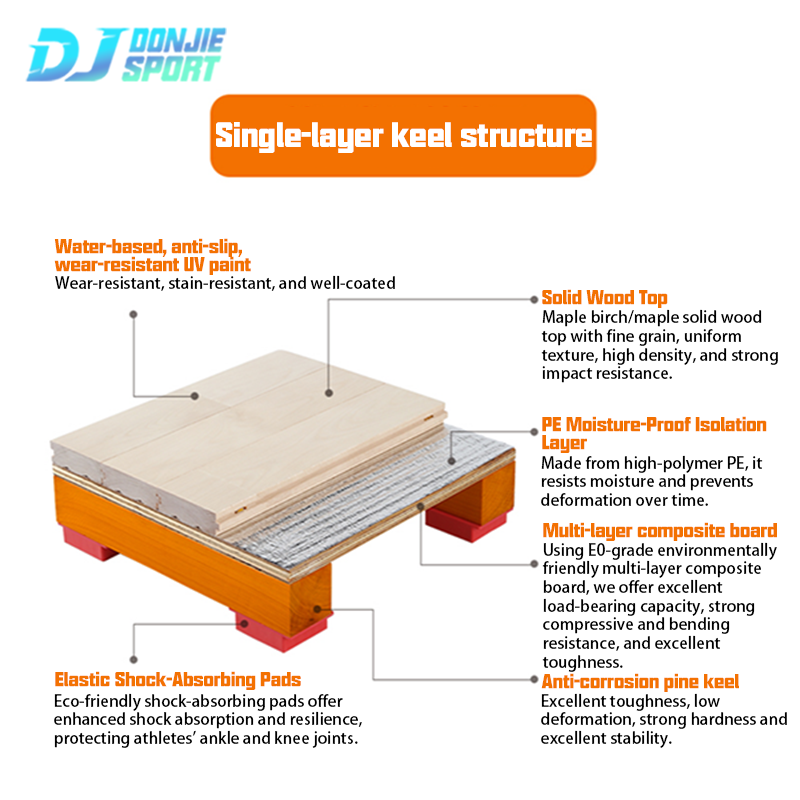

Premium Material & Structural System

Our basketball wooden sports flooring features a multi-layer design optimized for athletic performance, using industry-leading materials:

Core Panel Materials

Solid Wood Options: Hard maple (top choice for global stadiums, ideal for TV broadcasts) and oak/ash (high durability for high-traffic venues) .

Engineered Wood Options: 3-layer/5-layer composite with hardwood veneer (enhanced dimensional stability, suitable for humid regions) .

Full-System Components

Moisture Barrier: PE geotextile film to block ground moisture .

Shock Absorption Layer: PU/rubber pads (30%+ impact absorption) to reduce joint strain .

Load-Bearing Layer: Single/double treated pine joists (400mm spacing) for 1000kg/㎡ load capacity .

Stabilization Layer: 12mm+ OSB/plywood to prevent surface deformation .